Spectrum Scientific, Inc (SSI) has recently launched a range of optical coatings to meet the market need for increased reflectivity and sensitivity in the DUV and VUV, allowing users to unlock new applications in these spectral regions.

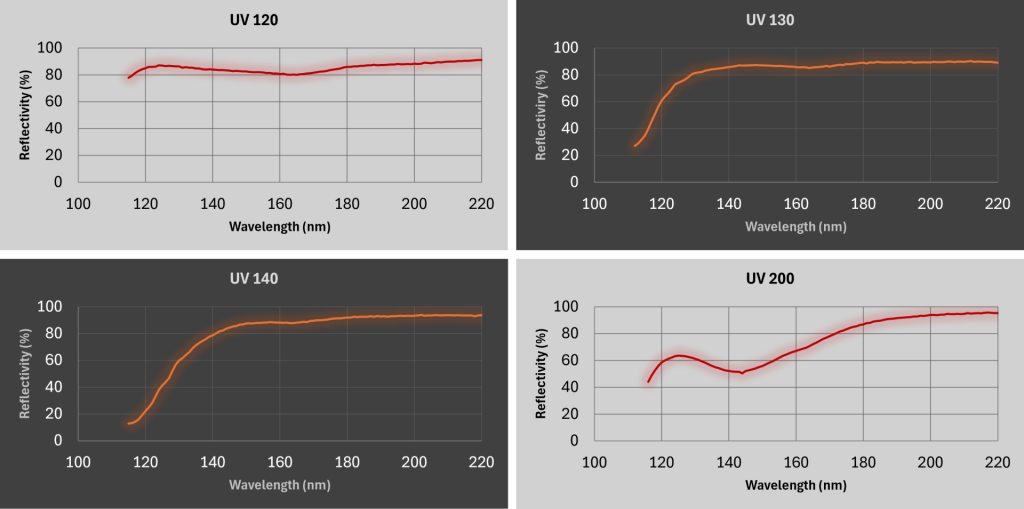

Our VUV optical coatings are available from 120 to 200 nm. They are predominantly used in the field of spectroscopy and analytical instrumentation, chemical analysis and space astronomy but can be used wherever high DUV or VUV sensitivity is required.

In an optical system, throughput = R^n where R is mirror reflectivity and n is the number of mirrors in the system, illustrating that the more mirrors there are in an optical system, the higher the overall loss of throughput, leading to a significant loss of photons by the time you reach the sensor for multi-component systems.

Typically our DUV and VUV coatings provide superior reflectivity of around 10% higher compared to other optical coatings in the market and as shown in the throughput formula, this increase in reflectivity is critical where high throughput and high sensitivity are required.

With advancing miniaturisation of optical instrumentation, incorporating smaller light sources and detectors, and the hunt for weaker signals, a 10% increase in the reflectivity of each mirror can be critical to successful measurements.

SSI’s DUV and VUV coatings offer a step change in reflectivity, allowing higher throughput in multielement optical instrumentation, increasing throughput and sensitivity. In conjunction with our ability to manufacture high volume aspheric mirrors and UV enhanced diffraction gratings, SSI offers a true UV capability to our customers, unmatched by other suppliers.

To learn more about our DUV/VUV coatings, dowload our White Paper